Future-ready your business with manufacturing sustainability

The United States Environmental Protection Agency (EPA) defines sustainable manufacturing as “the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources.”1 As the global manufacturing industry continues to expand, so does its contribution to greenhouse gas emissions (GHG), which contributes to global warming.

For this reason, policy makers, stakeholders, and consumers both in the U.S. and abroad are demanding more environmentally sustainable practices from manufacturers, which includes energy and water conservation and waste reduction. However, with the complexities and extensive value chains in manufacturing, this can be a challenge, especially since most manufacturers are small businesses with fewer than 20 employees (although these operations may have a large output of products).

Sustainability, though, delivers direct benefits to manufacturers. Implementing sustainable manufacturing practices can help reduce costs, improve recruiting and retention of employees, and possibly even improve sales. Increasingly, business customers and consumers prefer businesses that offer products that are more environmentally sustainable, which may impact their buying decisions. And many job seekers prefer to work for companies that embrace sustainability practices, which means that those that do may be a destination of choice for quality talent.

In addition, adopting technologies that enable environmentally sustainable practices can equate to better operational efficiencies, reduced energy costs, reduced waste production, and other overhead-related expenses.

What drives sustainability in manufacturing?

The manufacturing industry continues to grow. The most recent numbers from the EPA report that “industry” (manufacturing) accounts for 23% of greenhouse gas (GHG) emissions by economic sector. When electricity end-use is factored in, industry is the leading contributor of GHGs.3

These emissions are generated in various ways, including, but not limited to:

- The use of fossil fuels for heat and power and production of products, such as paint and plastics

- Machine emissions

- Chemical processes

- Leaks from processes and equipment

GHGs contribute to climate change and pollute the air, water, and soil. Manufacturing also consumes many of the world’s raw materials and produces a significant amount of waste.

Sustainability has become increasingly important to the manufacturing industry. As companies and leaders become more aware of their environmental footprint, many have been spurred to action to protect the health of our planet and our communities.

There are many options for companies to adopt a sustainable manufacturing model. They can consider ways to minimize fossil fuel consumption through renewable energy sources, which can make a significant impact on carbon emissions. According to the EPA, remanufacturing materials that are in limited supply, such as rubber and steel, can help to minimize carbon emissions because it saves 85% of the energy required to manufacture a new product.4 It also helps improve conservation of landfill space, which is the most detrimental form of waste disposal. The methane gas landfills release “is 80 times the warming power of carbon dioxide over the first 20 years after it reaches the atmosphere.”5

While exact figures are difficult to confirm, it’s estimated more than 7.5 billion tons of industrial waste is produced each year. Chemical manufacturing contributes the most hazardous waste. In 2021 it produced over 22 million tons.6

As technology continues to evolve to provide better insights and deliver operational efficiencies, it’s playing an important role in addressing both waste production and energy conservation.

5G and edge solutions for sustainability in manufacturing

The nature of manufacturing is energy- and waste-intense. Many new technologies can help companies address these challenges and reduce their impact on the environment. The foundation for these technologies is a reliable and secure core network. Legacy networks of copper don’t provide the speed, bandwidth, and latency needed to support today’s data-demanding tech. Fiber optic cable, however, does. In addition, fiber requires significantly less energy to transmit data than copper.

With a foundation of fiber in place, 5G business solutions level-up tech opportunities through providing more reliability, flexibility, availability, and capacity to wireless services. In addition, 5G’s ultra-low latency enables for real-time access to data—an imperative for manufacturing processes. This all equates to better operational and energy efficiency.

To better understand how much of an impact 5G can have on sustainability in manufacturing, AT&T collaborated with the Purdue Research Foundation of Purdue University to study how using 5G to monitor and adjust the operation of an air compressor would impact electricity usage and the carbon footprint of the machine. The Purdue team found that a company could expect to see a reduction of over 1,500 tons of CO2 every year for each air compressor that was connected to 5G. If 1,000 air compressors were connected, it could avoid 1.6 million metric tons of CO2e annually (CO2e stands for Carbon Dioxide equivalent and measures the total greenhouse gases emitted expressed as the equivalent of carbon dioxide). That’s the equivalent of more than 250,000 homes for a year.7

Next, edge computing (edge) delivers additional benefits through a decentralized model and stores data at the edge of the network, or near the end device where it’s accessed. This might be in a router or a Wi-Fi hotspot. Because of edge computing’s lower latency, data can be accessed in real time. Some manufacturing processes, like pharmaceuticals, require instant access to mission-critical information. Edge delivers this. In addition, multi-access edge computing (MEC) is a specific architecture or standard within edge. It’s important to manufacturers because it enables them to keep their data within a defined perimeter for critical processes and better security.

Hyperscalers, which is a type of data center that provides computing power and storage at enterprise scale, are cloud-based. These edge cloud services enable applications and processes that need to be performed in the cloud. Examples include smart factories, which rely on Internet of Things (IoT), artificial intelligence (AI), predictive maintenance, and supply chain management.

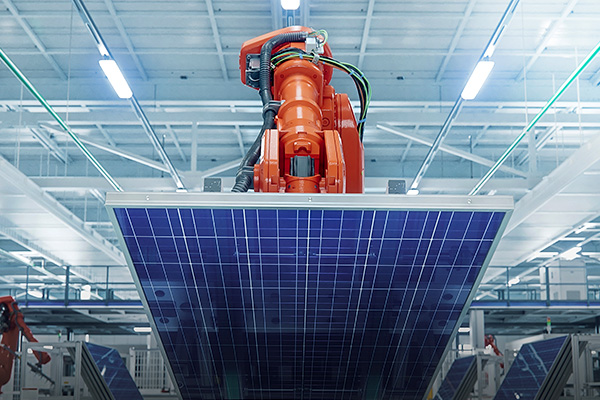

These technologies allow for more devices and equipment to be connected at once, enabling users to access data closer to real time. They’re also powering robotics and delivering insights into production that help to minimize line errors, detect anomalies, and reduce costly scrap—all of which can help improve manufacturing sustainability.

Driving business success through sustainability

Stay ahead of regulations and reduce energy and resource consumption. Learn why sustainability is important for business and staying resilient in a crisis.

IoT manufacturing for economic and environmental sustainability

IoT has an important role in sustainability, especially in manufacturing. Both process and discrete manufacturing relies on accuracy to deliver products that function as promised. For example, the ingredients used for drug production not only must be measured precisely, but the environment must remain stable to produce a safe and effective product. In discrete manufacturing, wafer production for semiconductors requires precise measurements of raw materials and chemicals for conductivity. And protecting processes from contamination is a top concern for all manufacturers.

IoT sensors on the factory floor provide more points for monitoring to help ensure quality, and any issues are predicted or detected before they impact production. This level of monitoring also minimizes unplanned downtime.

Since IoT can provide better insight, control, and management, it’s an essential technology for improving energy consumption to help reduce greenhouse gas emissions and a company’s carbon footprint. Specific opportunities include:

- Optimizing equipment operations and processes: IoT sensors enable for automation, which improves operational efficiency. Sensors also provide detection and alerts for when machines, including robotics, aren’t operating correctly or efficiently. Errors like this can cause machines to work harder, which can cause an increase in energy consumption and more frequent maintenance.

- Forecasting demand: IoT and machine learning can help manufacturers better predict demand and mitigate overproduction. It can also be a key factor in setting shut-downs and start-ups for employee management, waste reduction, and energy management.

- Predictive maintenance: When combined with machine learning, the data can determine the right time for maintenance. The IoT-based system sends an alert that it’s time to send out someone to repair or adjust the equipment. This helps improve sustainability in manufacturing by extending the lifespan of equipment, which can help minimize waste.

- Quality control: IoT sensors can help detect product defects, equipment abnormalities, and fluctuations in quality-impacting factors. It also gives manufacturers access to valuable data that they can analyze to identify where quality issues tend to occur and take corrective action. The net gain is energy efficiency and waste reduction.

- Warehousing: IoT enables smart metering in temperature and cooling systems for better electricity consumption and environmental controls like humidity in real time. IoT sensors can monitor servers and their capacity to operate only when needed.

- Fleet management: IoT-based telematics provide information to improve driver behavior. Idling, efficient routing, and braking can be improved with these insights. And for the cargo itself, temperature, humidity, vibration, and other factors that can cause spoilage and additional waste are monitored.

IoT can also lead to better sustainability practices through:

- Better supply chain visibility

- Smart inventory management

- Improved water consumption and usage

- Remote equipment monitoring and repair

- Tracking and adjusting the carbon footprint

The IoT-based data collected across the business enables for better energy consumption standards and to strive towards a net-zero impact on the environment.

Addressing carbon emissions across the value chain

Sustainability can be achieved in not only production, but the entire value chain. Actions include sourcing raw materials that are more sustainable and managing carbon emissions from the transportation and storage of goods.

The EPA has defined GHG standards and classifies three categories: Scope 1—owned or direct activities, Scope 2—purchased energy, and Scope 3—emissions from other company activities. Value chain emissions largely fall under Scope 2 and Scope 3. They require companies to consider partner and supplier sustainability practices in addition to their own to achieve a net-zero environmental impact.

Although manufacturing is a primary contributor to greenhouse gas emissions, there are technologies to help reduce its environmental impact. 5G, edge solutions, IoT, and machine learning are just a few of the tools that can help manufacturers meet the new sustainability standards being demanded of them. These technologies have the potential to significantly reduce greenhouse gas emissions and waste.

Why AT&T Business?

See how ultra-fast, reliable fiber and 5G connectivity protected by built-in security give you a new level of confidence in the possibilities of your network. Let our experts work with you to solve your challenges and accelerate outcomes. Your business deserves the AT&T Business difference—a new standard for networking.

1“Sustainable Manufacturing,” United States Environmental Protection Agency, Accessed Jan 26, 2024, https://www.epa.gov/sustainability/sustainable-manufacturing.

3“Sources of Greenhouse Gas Emission.” Environmental Protection Agency. . https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions.

4George A. McCraken, Roger Christiansen, Mark Turpin, “The Environmental Benefits of Remanufacturing: Beyond SF6 Emission Radiation”. EPA.gov. Accessed January 3, 2024. https://www.epa.gov/sites/default/files/2016-02/documents/conf00_mccracken_paper.pdf.

5“Methane: A crucial opportunity in the climate fight”. Environmental Defense Fund. Accessed January 3, 2024. https://www.edf.org/climate/methane-crucial-opportunity-climate-fight.

6Bruna Alves. “Hazardous waste generated in the United States 2001-2021, by sector.” Statista. November 6, 2023. https://www.statista.com/statistics/1267138/hazardous-waste-generation-in-the-united-states-by-top-industries

7“Assumptions and References for Household Carbon Footprint Calculator,” EPA.gov, Accessed Dec 13, 2023, https://www.epa.gov/ghgemissions/assumptions-and-references-household-carbon-footprint-calculator